3D Printing Makes It Easier to Implant and Fix Electronic Devices

Lancaster University researchers have devised a way to 3D-print flexible electronics using a conducting polymer and directly print electrical structures on or in live creatures. The researchers hope their additive manufacturing approach can create patient-specific implants for real-time health monitoring and medicinal treatments like treating epilepsy or pain.

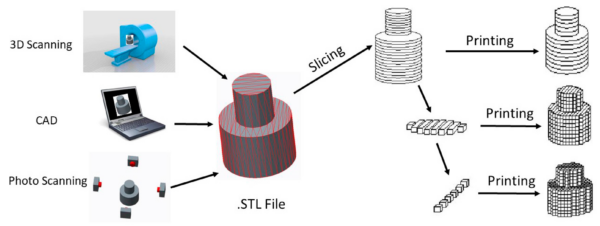

Light-transmitting 3D printing generated well-resolved, conductive, micrometer-scale features.

The researchers employed polypyrrole and an erbium-doped fiber laser at 100 MHz and 780 nm. They used multiphoton manufacturing to construct 3D objects with embedded electronics after screening ink components for cytocompatibility in silico..

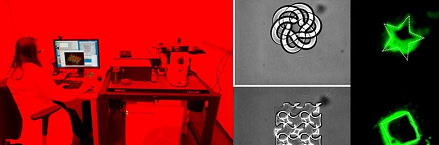

The researchers 3D-printed an electrical circuit directly within a silicone matrix using a nanoscribe, a high-resolution laser printer. The 3D-printed electronics stimulated mouse neurons in vitro after OCT verified the printing process.

In vitro mouse brain slices got 3D-printed electrodes.

In the second stage, researchers 3D-printed conducting structures directly in C. elegans nematode worms, proving that the entire process—ink compositions, laser exposure, and printing—was safe for living things. Researchers chose C. elegans is excellent for evaluating biosafe laser-based in vivo printing technologies in biomedicine owing to its great sensitivity to heat, desiccation, and physical harm, the researchers claimed in their report. “Laser printing live C. elegans would need the lowest laser power for ink polymerization and biocompatible ink components,” they stated.

The researchers “tattooed” conductive patches onto small worms using smart ink and lasers, researcher Alexandre Benedetto said. He added the results proved the researchers might employ the technology to achieve medical application resolution, safety, and comfort.

The Lancaster team’s approach might enable biomedical breakthroughs, but advancements in infrared laser technology and smart ink composition and distribution are needed to bring 3D-printed medical devices to the clinic. The team’s technology might be utilized in laser dentistry or eye surgery to repair implanted devices, according to researcher John Hardy.